JEWELLERY CASTING

Precision in Every Grain

From artisan workshops to high-volume gold and silver foundries, Certus offers two equally high-performance jewellery investment brands: PRESTIGE and SPECTRA.

Both are engineered with the same material science, quality control standards and production discipline – designed to deliver repeatable, defect-free casting results.

PRESTIGE focuses on premium surface quality, faster devesting and advanced proprietary technologies.

SPECTRA delivers the same level of reliability and consistency, optimized for streamlined production workflows and process stability.

Why jewellery casters choose Certus

- Consistent batch-to-batch performance

- Smooth, high-definition casting surfaces

- Controlled and repeatable thermal expansion

- User-friendly mixing and bubble-free moulds

- Reliable results in vacuum or centrifugal casting

Every Certus jewellery investment is tested under real production conditions to ensure identical results – flask after flask.

PRESTIGE ORO / SPECTRA ADVANCE

Ultra-premium gypsum investment developed for 18–22K gold casting where surface perfection is non-negotiable. ORO delivers exceptionally smooth finishes, stable expansion and clean separation after casting. Its Blast Away technology significantly reduces devesting time and post-casting clean-up.

Ideal for: High-karat gold, fine detail work, premium jewellery production.

PRESTIGE UNICAST / SPECTRA TRIVEST

A versatile, high-performance investment designed for workshops casting multiple alloys. UNICAST provides balanced working time, excellent slurry flow and controlled expansion - helping maintain surface quality across gold, silver and bronze production.

Ideal for: Mixed alloy casting, flexible production schedules, reliable everyday performance.

PRESTIGE SIGMA / SPECTRA CAST

Engineered specifically for silver and brass casting, where porosity control and dimensional stability are critical. SIGMA maintains mould integrity even in large or complex trees, delivering dense castings with reduced surface defects.

Ideal for: Silver production, large trees, low-porosity requirements.

PRESTIGE SPARKLE / SPECTRA SHIELD

Specially formulated for Stone-in-Place casting. SPARKLE creates a protective thermal environment that helps safeguard diamonds, CZ and many gemstones during burnout - while preserving fine surface detail and mould strength.

Ideal for: Stone-in-place jewellery, delicate settings, reduced stone damage risk.

PRESTIGE OPTIMA / SPECTRA GENESIS

High-strength, high-expansion investment optimized for 3D-printed resin patterns and hybrid wax systems. OPTIMA ensures excellent detail reproduction, reduced ash residue and stable burnout performance - even with modern pattern materials. Includes Blast Away technology for easier devesting.

Ideal for: Resin patterns (SLA/DLP), complex geometries, white gold and palladium alloys.

INDUSTRIAL PRECISION CASTING

High-Temperature Reliability for Demanding Alloys

Industrial investment casting requires materials that can handle extreme thermal loads and maintain dimensional accuracy under stress. From stainless steel to non-ferrous and aluminium alloys, Prestige Industrial Powders are built to perform where precision and durability are critical.

For platinum, stainless steel and superalloy applications, FERRO-VEST VHT delivers superior strength and thermal stability through its two-component phosphate-bonded system. Its special particle sizing and phosphoric acid binder ensures perfect mould integrity at casting temperature to maintain an exceptionally smooth uniform casting surface that greatly reduces times in finishing.

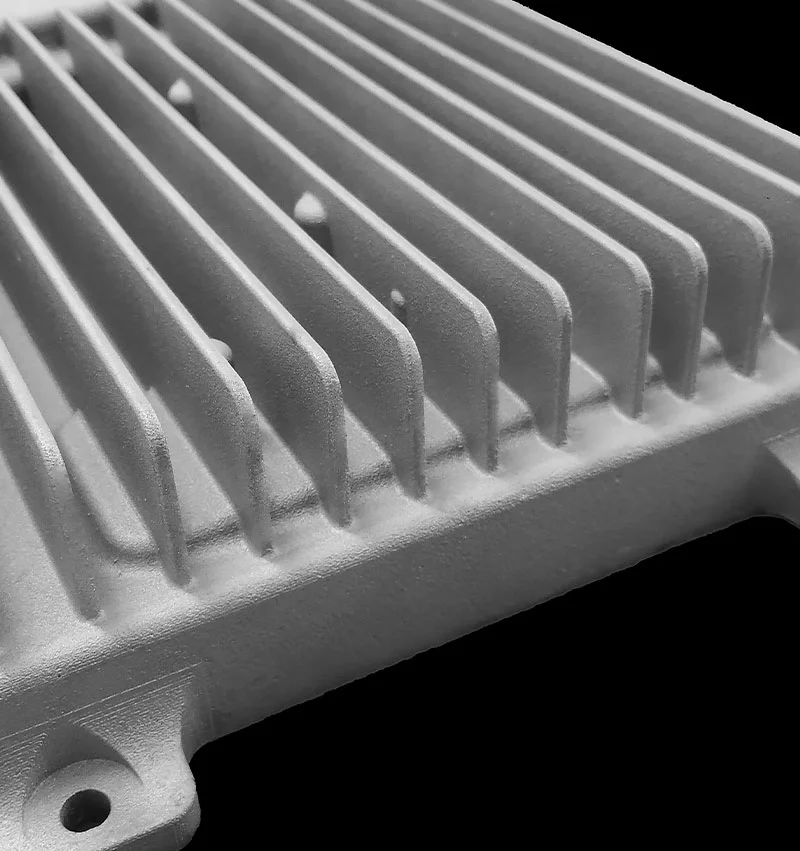

For large, complex non-ferrous components, “POWERCAST” provides the mechanical stability required for massive flasks and heavy castings. Its controlled particle size distribution with a low water demand reduces shrinkage and micro-cracking, even in the thickest sections of castings. The resulting mould offers the permeability required to quickly evacuate gasses produced by the metal for a uniform casting surface, essential for industrial prototypes, turbine components, and high-value metal sculptures.

Each production batch produced by Certus undergoes triple quality control – raw material testing, in-process analysis, and independent foundry trials – ensuring zero-defect consistency across all industrial investment formulations. Prestige powders give engineers the confidence to achieve net-shape results with process reliability for reduced scrap rates and positive ratio’s.

ART & SCULPTURE CASTING

Where Art Meets Engineering

In the world of bronze, brass and aluminium sculpture casting, surface quality and mould stability define the final artwork. POWERCAST by Prestige combines the precision of industrial technology with the aesthetic demands of fine art.

Formulated with graded refractory grains and enhanced flow modifiers, Powercast ensures a creamy, bubble-free slurry that fills every contour of the wax model – from monumental sculptures to intricate art objects. Its exceptional thermal stability prevents cracking during burnout and ensures that the investment breaks away cleanly after pouring.

Artists and foundries appreciate the time saved during cleaning and finishing: smoother surfaces, fewer inclusions, and consistent results even across large moulds. The low-residue formula minimizes dust during devesting and can be used seamlessly with both traditional and modern vacuum mixing systems. From individual art studios to industrial art foundries, Powercast enables the creation of pieces that preserve every fine texture and surface nuance envisioned by the artist – transforming creative detail into durable metal.

TIRE CASTING

Precision Moulds for the Rubber Industry

The production of high-performance tire moulds demands a unique type of investment material – one capable of reproducing complex tread patterns with micron-level fidelity, while maintaining excellent dimensional stability during long burnout cycles.

POWERCAST “T” has been specially engineered for aluminium permanent-mould casting in tire and automotive applications. With its high permeability and anti-foam additives, it eliminates trapped air pockets and surface irregularities that could distort tread geometry. The formulas carefully balanced expansion and particle sizingprevents cracking and warpage even in very large or multi-segment moulds.

Its extended burnout profile – typically 24 hours with controlled intermediate holds – ensures uniform dehydration and stable mould walls. The result is a defect-free, smooth-surfaced cavity ready for precision aluminium pouring. Manufacturers benefit from reduced rework, consistent pattern accuracy, and reliable repeatability across multiple mould segments.

By combining the process discipline of industrial casting with the material science of jewellery investment powders, Prestige Powercast “T” sets a new benchmark for the tire-mould industry: flawless reproduction, stable performance, and measurable cost efficiency.